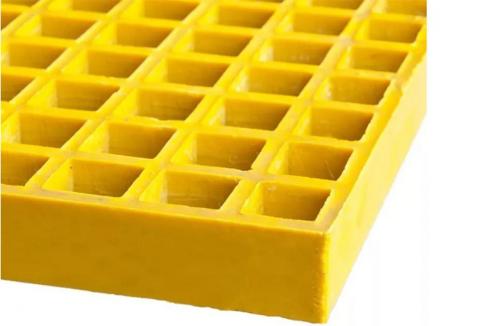

Sino Composite offers customer with Molded FRP Grating system. This grating is with advantages of light weight, anti corrosive, high strength and cost efficient. Various of resin, color and specification are available.

Molded FRP(Fiberglass Reinforced Plastic) grating is composed of alternating directional layers of continuous glass fiber for strength, with resin to consolidate the fibers and provide the shape and corrosion-resistance. Due to its bidirectional strength, molded grating can tolerate cutouts in the panel to allow pipe or equipment penetrations without requiring additional support around the opening. Molded grating has very high impact tolerance, as well as the highest chemical resistance of any fiberglass grating. It can be made slip-resistant by adding grit to the surface.

Sino Composite offers customers with both standard and customized panels. We have more than 100 types of standard panels moulds, which could meet almost all the market’s demand.

Sino Composite also offers customers with required molded gratings. Our engineer team will provide with free and professional support.

Sino Composite manufactures FRP gratings are available in various of slip resistant surfaces.

FRP molded grating available surface options:

Partially standard FRP molded grating specifications and sizes.

Sino Composite uses different resins to achieve different environments. Covering all resin application ranges, our professional sales team will recommend different resin substrates according to customer needs.

Resin System

During nearly 20 years of FRP grating production time, our products are widely used in various industries. Petroleum industry, chemical industry, municipal construction, marine engineering, solar energy, architectural decoration, etc.