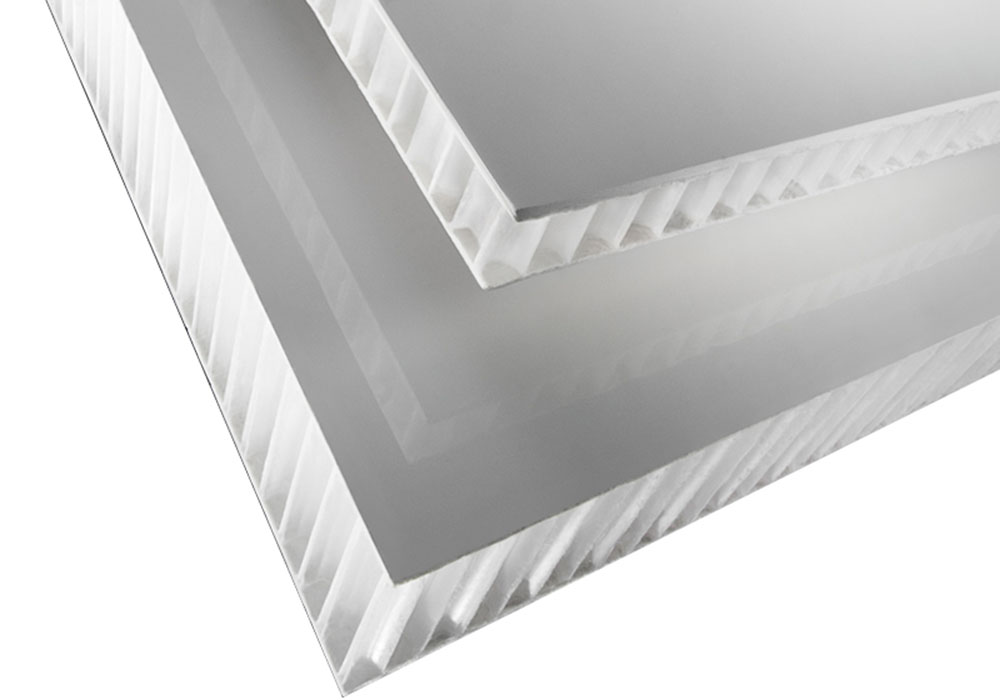

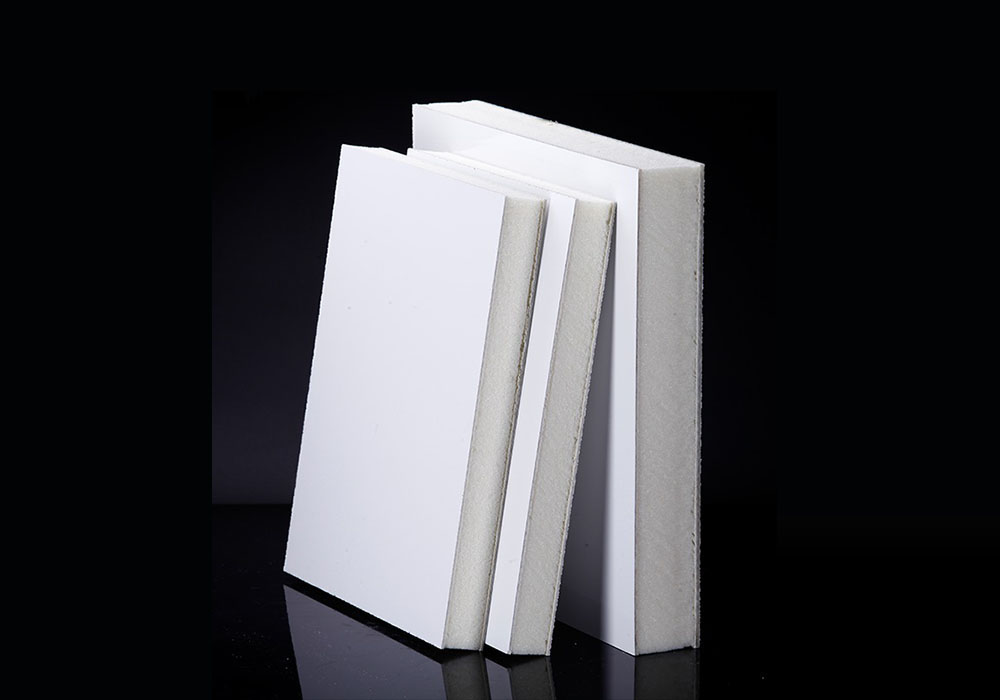

FRP Sandwich Panels is a sandwich structure panel formed by using glass fiber reinforced plastic as the inner (outer) panel, and using core material under certain pressure.

FRP Sandwich Panel Structure:

FRP plate (inner panel) + core material (PP, EPS, XPS, PU, etc.) + FRP plate (outer panel).

It is mainly used for trucks, vehicles, refrigerated carriages, RVs, freezers, prefab houses and building wall partitions.

Mechanical Properties

No | Test Project Name | Unit | Result | Standard |

1 | Tensile Strength | MPa | 124 | GB/T1447-2005 |

2 | Bending Strength | MPa | 182 | GB/T1449-2005 |

3 | Compressive Strength | MPa | 107 | GB/T5258-95 |

4 | Shear Strength | MPa | 102 | GB/T1450.2-2005 |

5 | Impact Strength | MPa | 104 | GB/T1451-2005 |

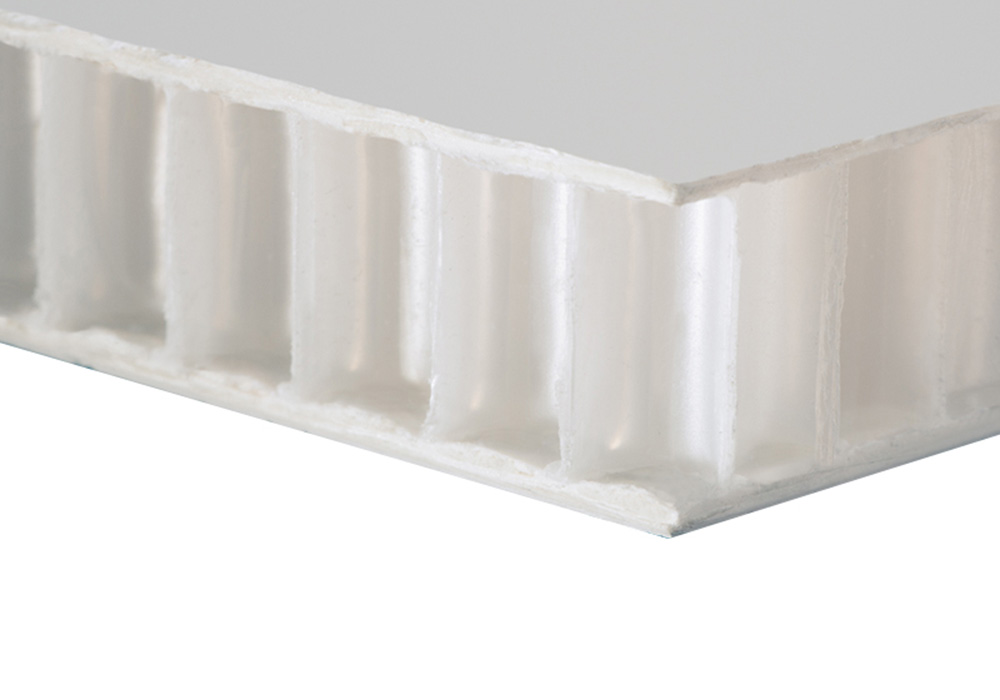

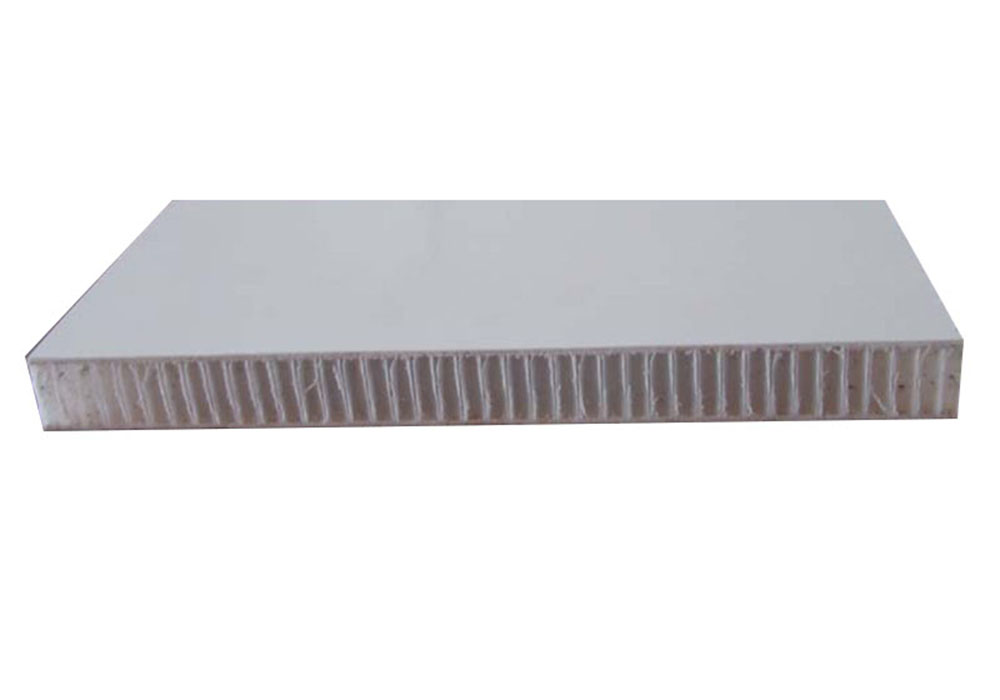

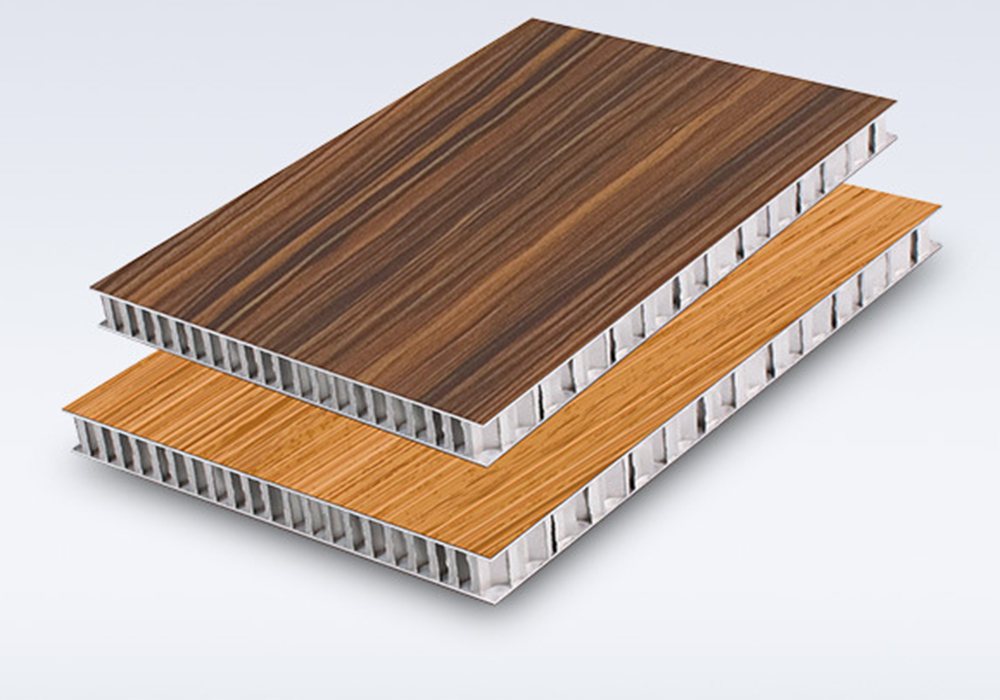

FRP PP Honeycomb Sandwich Panel

FRP PP Honeycomb sandwich panel is with two outer layer of FRP sheets under the pressure to an inner core of PP honeycomb.

PP honeycomb core is a new structural material processed from PP (polypropylene) according to the bionic principle of honeycomb

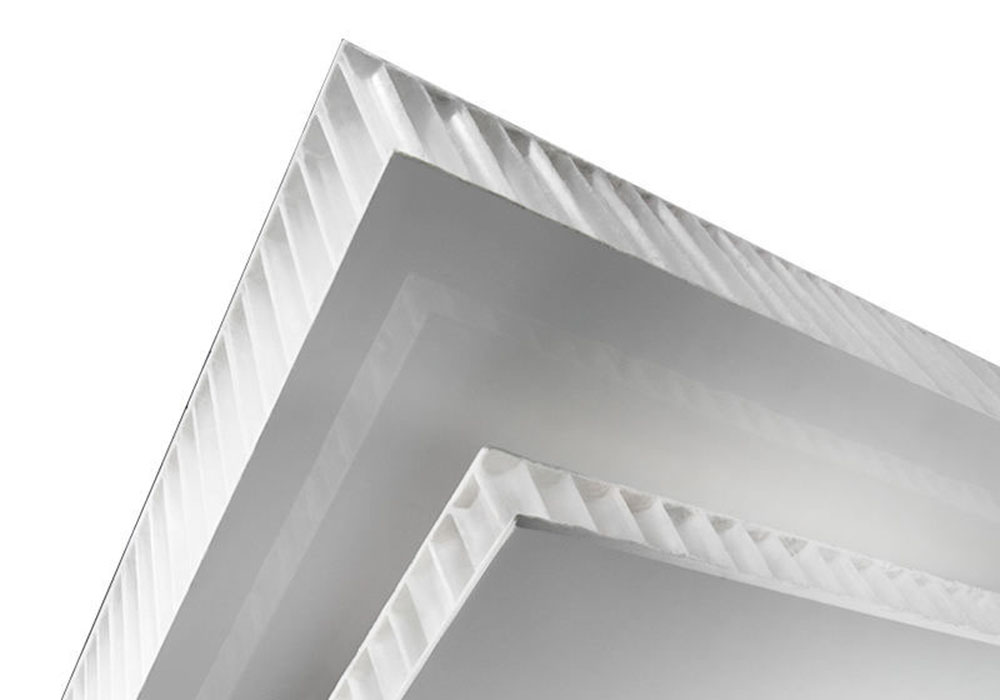

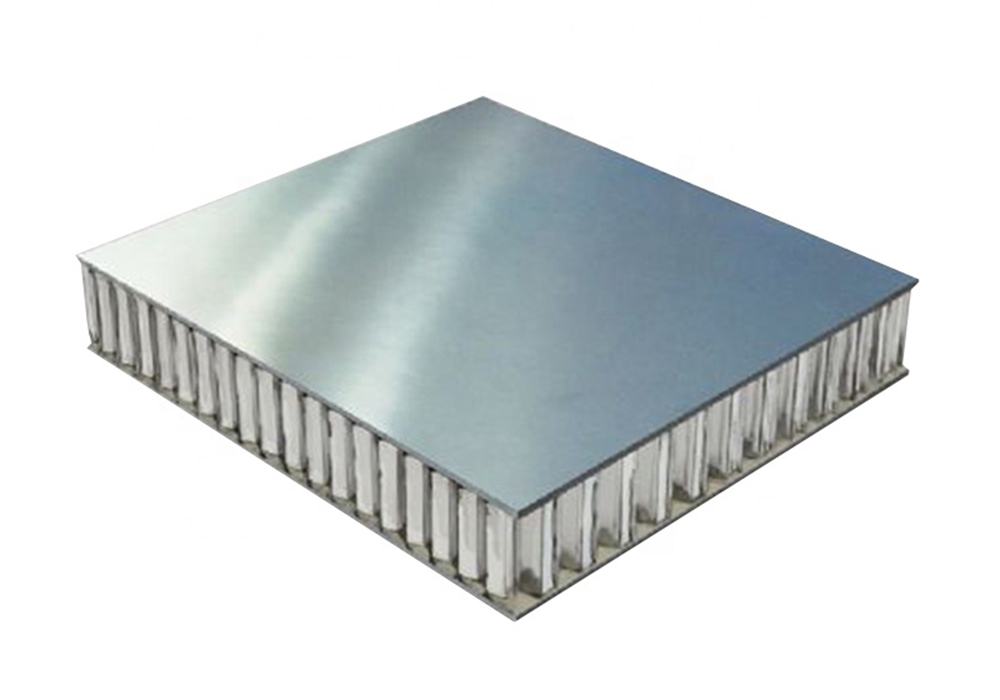

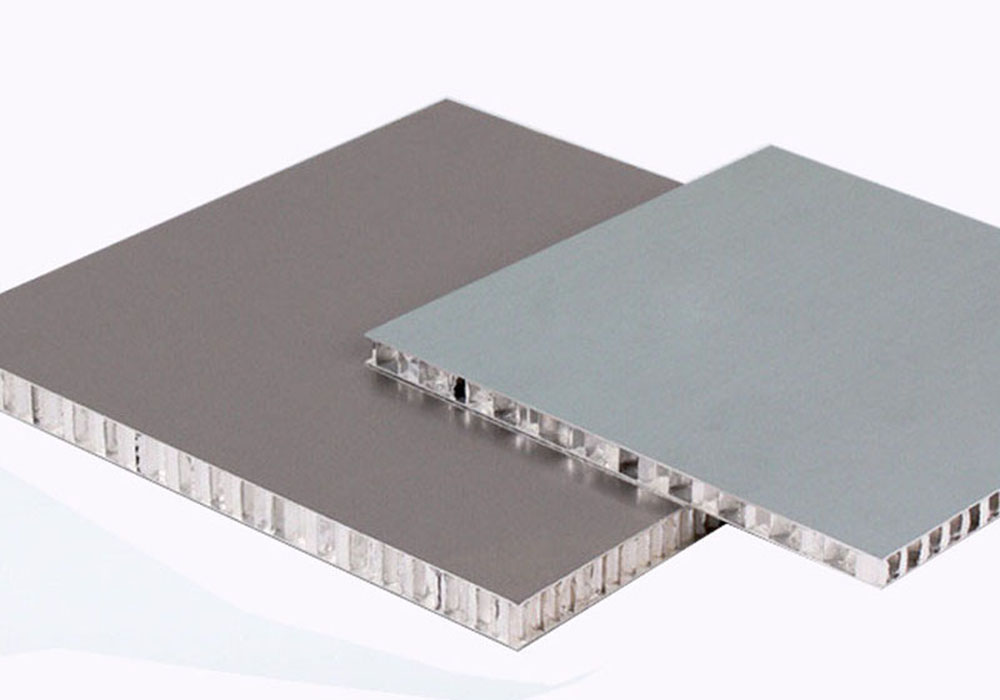

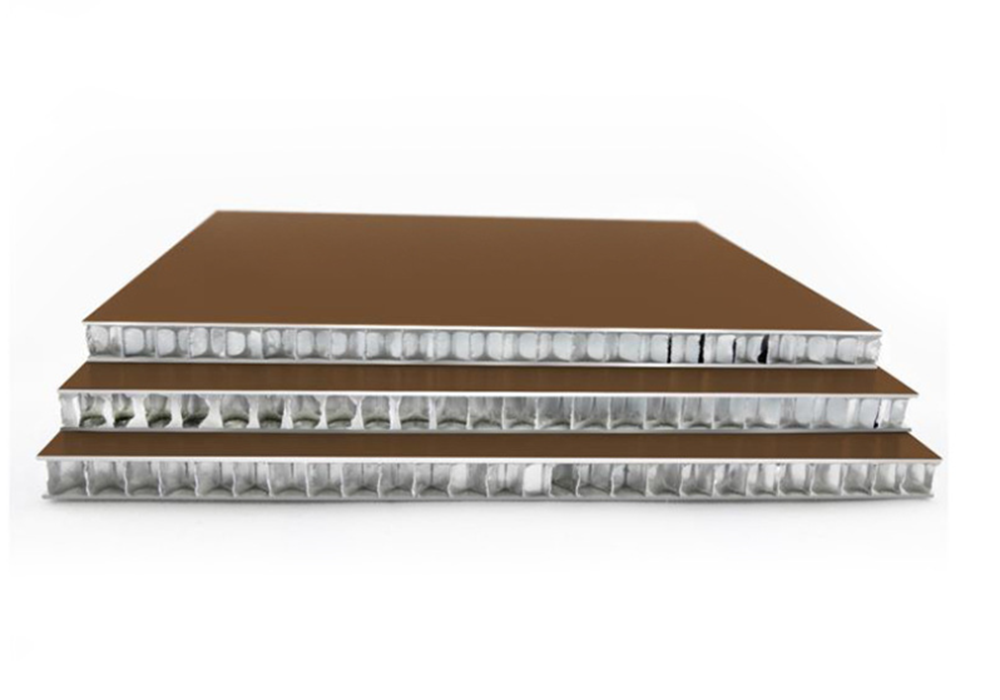

FRP Aluminum Honeycomb Sandwich Panel

FRP aluminum Honeycomb sandwich panel is with two outer layer of FRP sheets under the pressure to an inner core of aluminum honeycomb.

The aluminum honeycomb core is a regular hexagonal honeycomb core that is bonded, laminated and stretched by multiple layers of aluminum foil. The aluminum honeycomb core has sharp, clear cell walls, no burrs, and is suitable for high-quality core-to-face bonding and other uses. The core layer of the honeycomb panel is a hexagonal aluminum honeycomb structure, and the dense honeycombs pinned against each other are like many small I-beams, which can disperse the pressure from the direction of the panel, so that the panel is evenly stressed, and it ensures that the panel can be kept with high flatness in a large area .

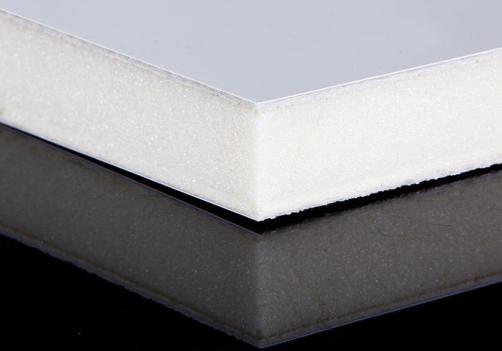

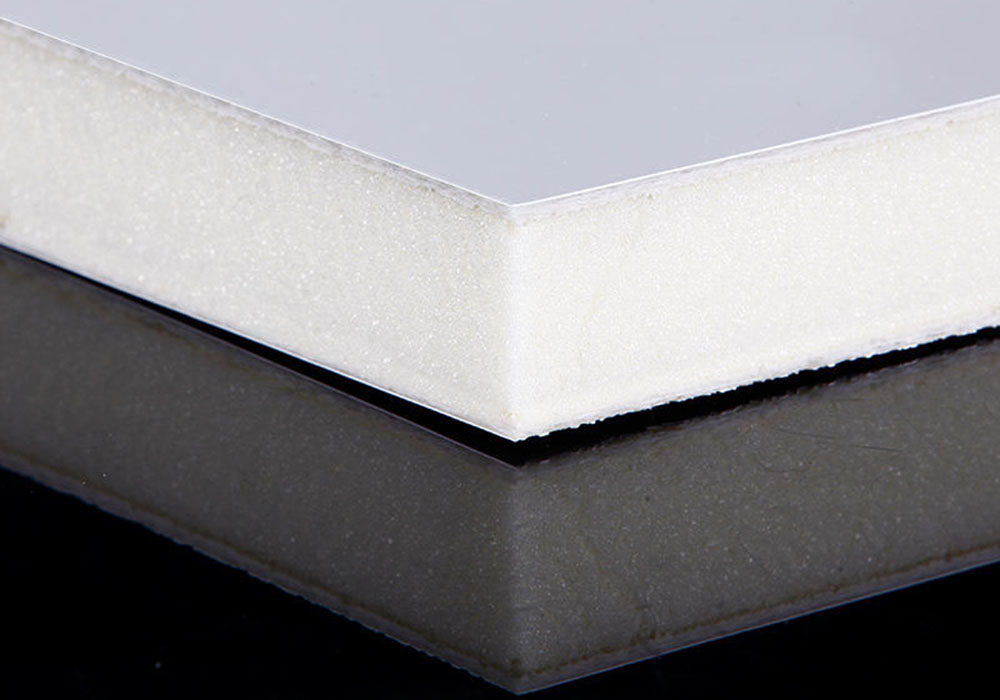

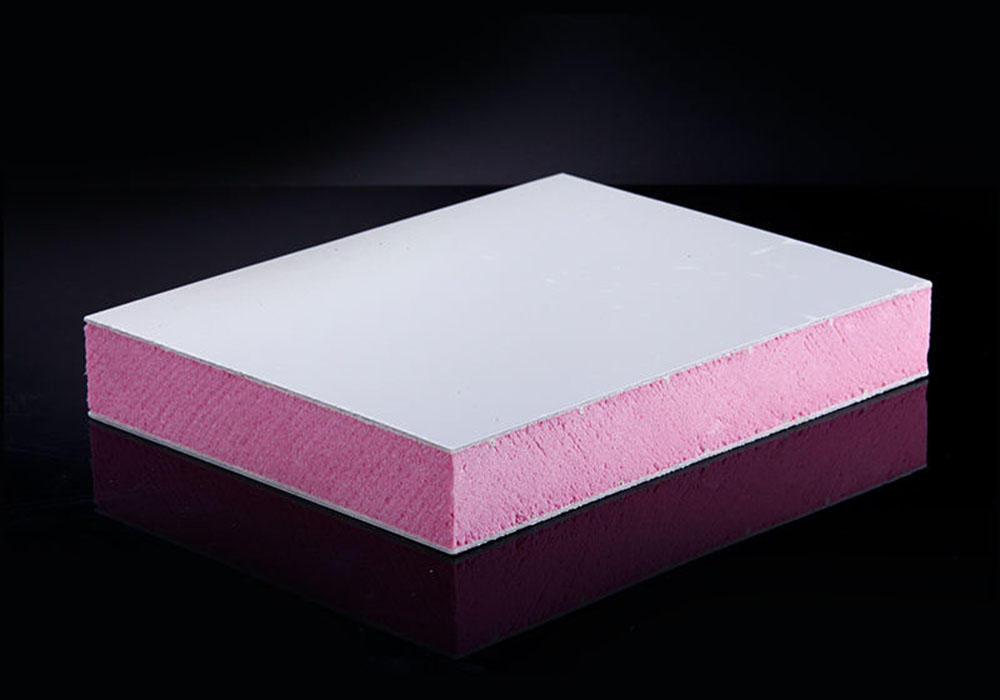

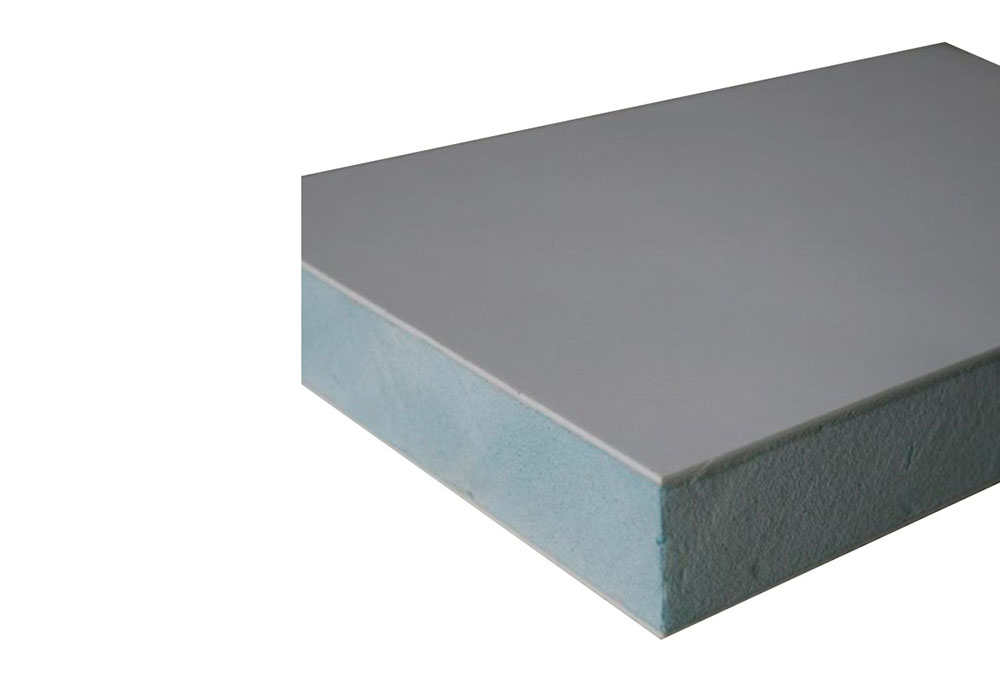

FRP XPS Insulation Foam Core Sandwich Panel

FRP XPS sandwich panel is with two outer layer of FRP sheets under the pressure to an inner core of XPS material.

XPS core is the extruded board, which is with a continuous and uniform surface layer and a closed-cell honeycomb structure produced by the extrusion process of polystyrene resin and other additives. The thermal insulation material of the structure can have different pressures (150-500Kpa), having the same low thermal conductivity (only 0.028W/MK), excellent thermal insulation and compressive properties. The compressive strength can reach 220-500Kpa

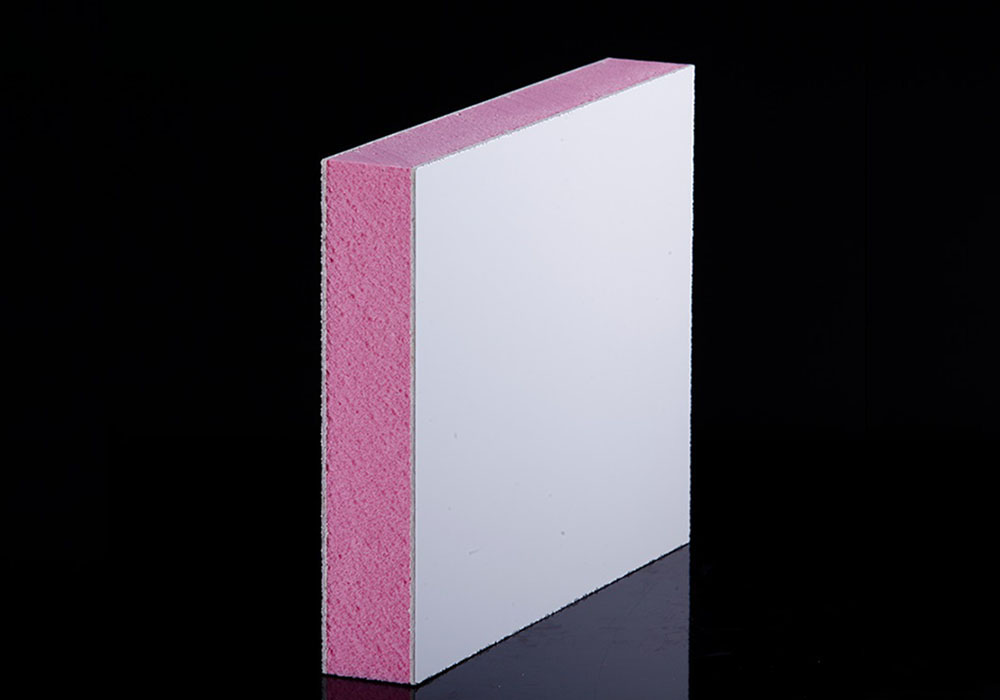

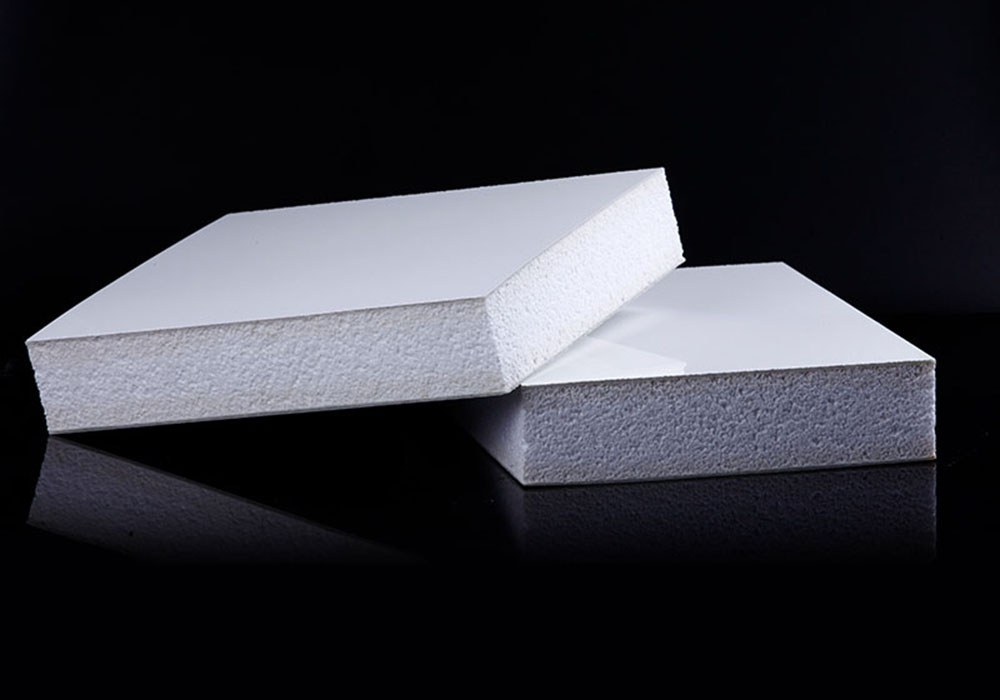

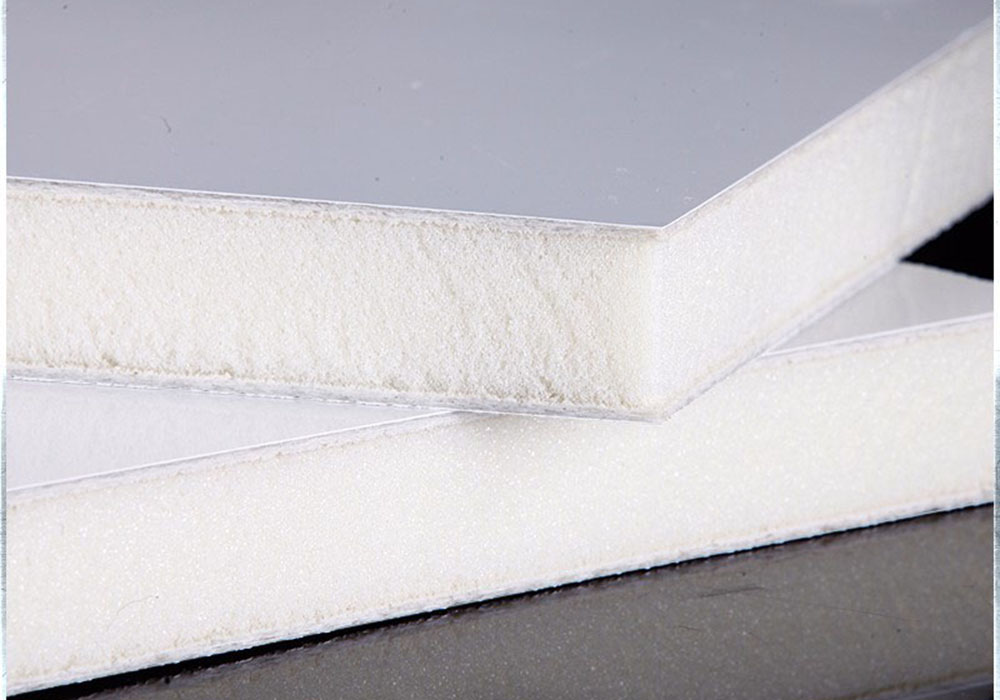

FRP EPS Insulation Foam Core Sandwich Panel

FRP EPS sandwich panel is with two outer layer of FRP sheets under the pressure to an inner core of EPS material.

EPS is polystyrene foam board, also known as foam board. EPS board is a white object made of expandable polystyrene beads containing a volatile liquid foaming agent and heated in a mold after pre-heating. It is with structural characteristics of closed cells property.

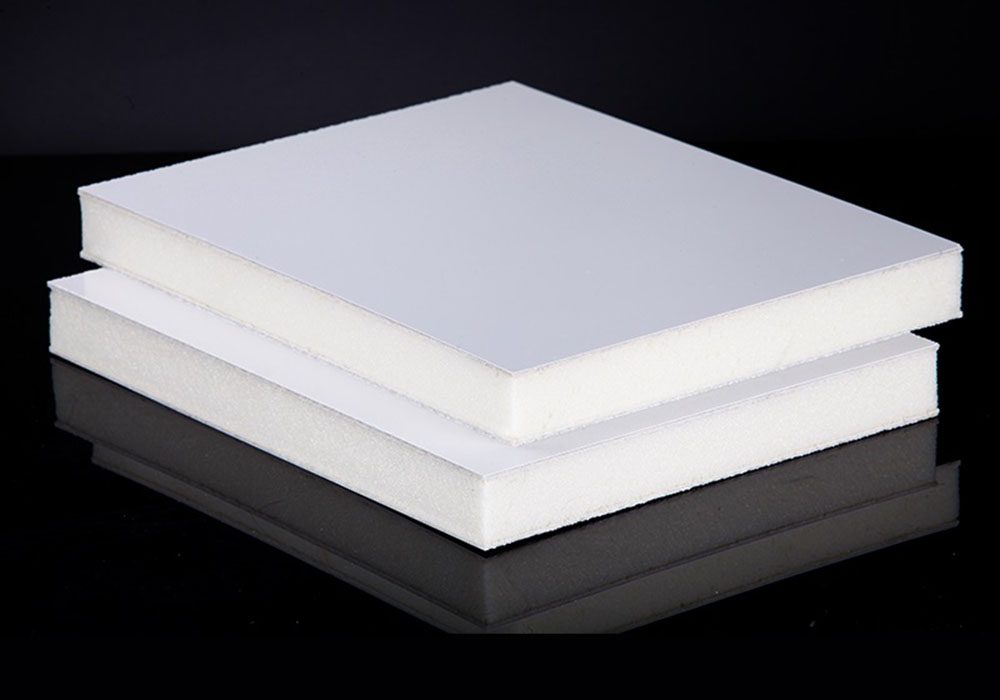

FRP PU Core Sandwich Panel

FRP PU Core sandwich panel is with two outer layer of FRP sheets under the pressure to an inner core of PU material.

PU core/board also called polyurethane core is the material with best thermal insulation property.

Insulation/refrigeration/dry cargo compartments

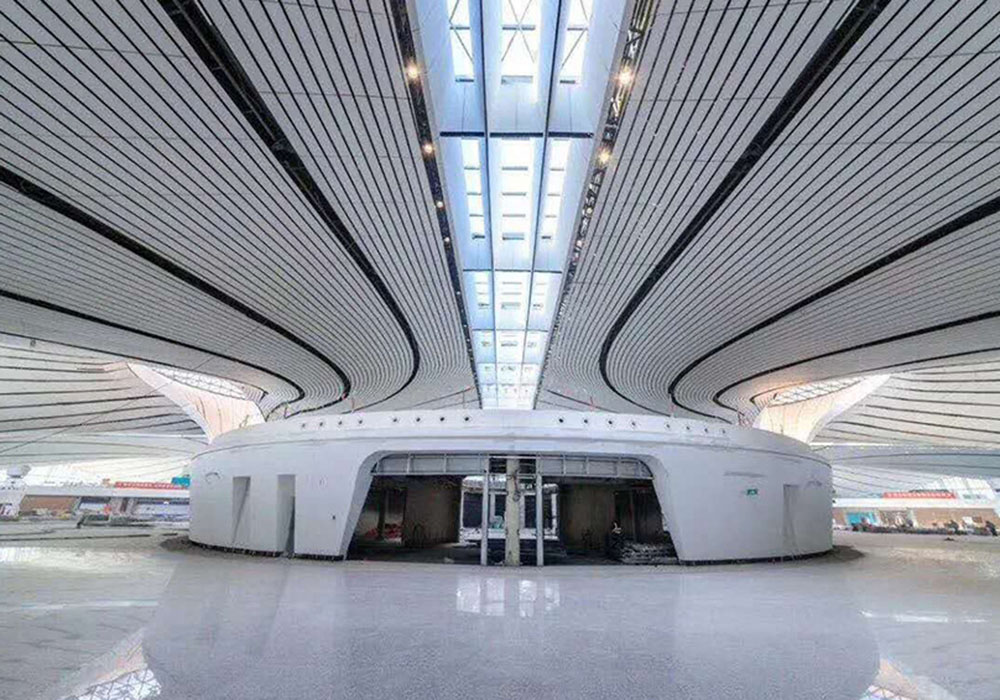

large-span structural roofs and walls

Thermal insulation (or fireproof) workshops

Purification workshops

Prefabricated houses

Cold storage

Enclosure system

Container houses, etcFRP Sandwich Panel Advantage

1. Light weight: 30-40% lighter than traditional products.

2. Thermal insulation performance: The thermal conductivity of the FRP panel is about 0.23W/m2.K, the thermal conductivity of the rigid polyurethane foam is 0.018-0.028W/m2.K, and the total heat transfer coefficient K value can be lower than 0.3W/m2. K.

3. Surface properties: The surface of FRP has extremely strong tensile strength, bending strength and impact toughness without deformation. It has excellent chemical stability to the atmosphere, rain and general concentration of acid, alkali, salt and other media.

High surface finish, anti-ultraviolet, good gloss retention, no discoloration, easy to clean, especially suitable for all kinds of carriage advertisements.

4. Impermeability: Double-sided FRP panels are impermeable and have excellent water resistance.

5. Flame retardant performance: The flame retardant index of FRP sheet conforms to the national standard B2 level.

6. Product life: 4-6 times longer than traditional domestic products.

7. Ease of maintenance: there is no obvious repair marks after repairing, which is unmatched by steel and aluminum panels.

8. Environmental performance: FRP surface has no volatile and corrosive substances, and the sandwich insulation board is filled with fluorine-free polyester foam, which is green and environmentally friendly.

FRP Sandwich Panel Relevant Parameter Values

1. The sound absorption coefficient of FRP composite board: it can be reduced to below 20 decibels;

2. The flame retardant grade of FRP composite board: according to GB-8624-1997, it is a flame retardant grade B1;

3. Heat transfer coefficient of FRP composite board: 0.57-0.117Kcol/m2 (50-100mm thick). Specifically, the thermal insulation value of FRP composite board is 17 times that of concrete, 1600 times that of aluminum, and 450 times that of steel. times, which is 1/4 times that of glass;

4. In the temperature difference range of -40℃-120℃, no cold brittleness and softening will occur. The thermal expansion coefficient is 2.5×10-7mm/Mm/℃, and thermal deformation and displacement are not easy to occur;

5. The impact strength is 200-350 of ordinary glass